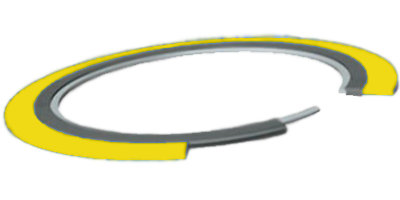

Spiral wound gaskets have proven to be the most reliable sealing element for use in difficult, critical and arduous duties. Spiral wound gaskets are wield used in Refinery, Petrochemical, Chemical, Steam lines and Process Industries.

Download Gasket Brochure

Standard Profiles

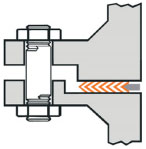

Type:- C

- Spiral wound sealing element.

- Wide choice of materials for filler and metal strip

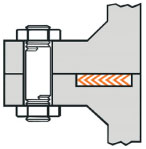

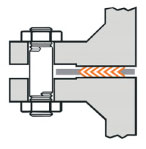

Type:- CS

- Spiral wound sealing element.

- Solid metal outer ring

- Wide choice of materials for filler and metal strip

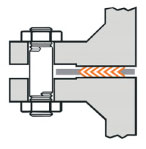

Type:- SI

- Spiral wound sealing element.

- Solid metal inner ring

- Wide choice of materials for filler and metal strip

Type:- CSI

- Spiral wound sealing element.

- Solid metal inner and outer ring

- Wide choice of materials for filler and metal strip

| Technical Details | |

| Metal Winding Material | Gasket Nominal Thickness |

| Stainless Steel 316L,316,316TIC,394,321,310,347Duplex | 3.2mm |

| Monel400 | 4.5mm |

| Inconel 600,625 | 6.4mm |

| Nickel 200 | 7.2mm |

| Titanium, Hastelloy,Incoloy 800,825 | |

| Filler Materials | Temperature Units | Centering and Inner Ring standard materials |

|---|---|---|

| Non Asbestos | 260℃ | Carbon steel |

| Ceramic | 800℃ | Stainless Steel 316,304,410,316L,316TI,Duplex |

| PTFE | 260℃ | Monel Nickel Incoloy |

| Graphite | 550℃ | Titanium inconel 600, 625 |

| Standard Thickness 3.2mm | ||

| Flange Suitability | ||

| BS1560 and ANSI B16.5 1/2 "-24" 150-2500ibs | ||

| BS10 Tables D-T | ||

| B4504 10-250 Bar | ||

| MSS SP 44 26 "-60" 150-900lbs | ||

| API 605 26 "-60" 150-900lbs | ||

| DIN |